A.The production of the Secretary universal crusher combination of domestic and foreign advanced experience of the industry to transform the production of new equipment, light weight, low energy consumption, blade material, long life, easy to clean.

★ machine looks nice, color coordination, paint firm.

★ into the hopper, crushing room, sieve bucket is the separation of design and easy handling.

★ buffer room to feed and imported curtain design, to prevent material splashing.

★ The anterior and posterior wall of the the broken room with double glazed, low noise.

★ pulley has a shield, safe and reliable.

★ has cleaning insurance valves.

★The motor mounted on the over load protection devices and power supply interlock protection system.

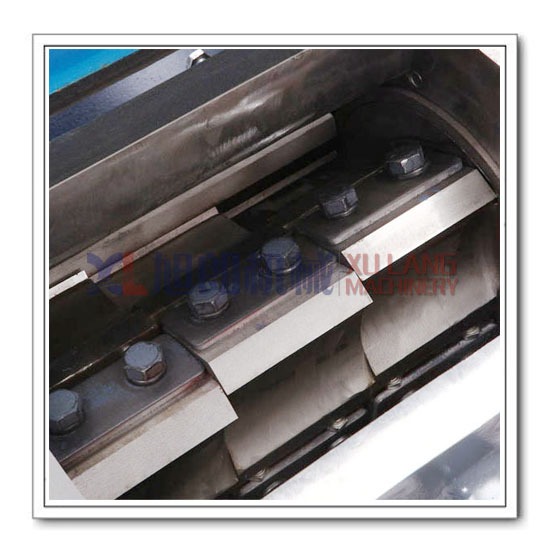

★ imported high quality tool steel, a special tool, particularly durable, tool installation design scalable to adjust for multiple sharpening with a blunt, and repeated use, long service life.

★The processes mature, the box, knife and other important parts of the overall processing, to ensure that the fitting accuracy. Cutting knife stand for the cascade cut design, so that the cutting force decomposition, resulting in doubling of cutting force.

★ reasonable structure, convenient operation, energy saving and durable, practical and economical.

★ universal plastic crusher, sealed bearings, bearing rotation for a long time to maintain a reasonably good knife design products into tablets of uniform, heat shrink tool holder, the appearance of the exterior design and generous.

Two. This machine is suitable to use Chinese herbal medicine, chemical materials, the lower hardness of ore as well as polystyrene, polypropylene, nylon, plastics and PVC foam soft material waste, defective or injection nozzle Broken. Such as replacement of the sieve plate, and adjust the blade clearance, and also crushing blow film, rolling film, sheet, sheets and other plastic waste. |