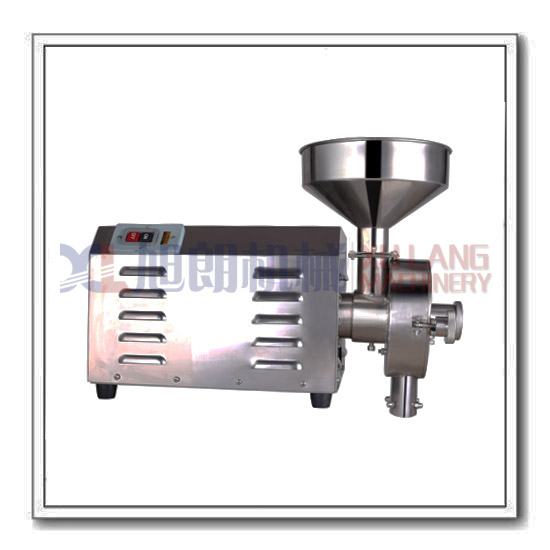

Guangzhou Xu Long Machinery Co., Ltd. is a pioneer in the development of whole grains milling machine manufacturers, the company technological transformation sector has been committed to continuous improvement and upgrading of the mill, operating performance, stable quality, smooth feed, milling fineness lower noise and vibration, beautiful appearance and so strive for excellence, goodness and beauty! Since the launch of the 820 milling machine, the machine a lot of peers are mainly small workshops to imitate the images many of its peers, dealers crazy to copy, to deceive the majority of customers to make profits, the majority of customers to pay attention to identify, prevent deceived! Has been imitated, never to be surpassed!

Working principle

Connecting shaft and motor shaft is directly connected to the operation of the motor starts to drive the connecting shaft and set in the axis of the disc connected with running. Material from the hopper into the mill set to be grinding, lap spindle and milling sets the relative operation, the breaking force of the materials minced into small pieces particles; undercooked ground after small particles are brought into the spiral motion of the disc two middle of the grinding, grinding the relative operation of the piece of tooth pattern, so that the material was crushed into small particles (powder) in a short time; powder from the grinding of the teeth ditch outflow and, Shuaixiang around, be mounted on the scratch on the disc powder taken off the board, out of the powder outlet.

2012 the latest features:

1, the regulator of the new machines no longer need to tighten the nut to secure the damper to adjust to the specified location, operation of the machine will not affect the regulator where the fixed position, no longer needs to be fixed. The old section of the machine adjusted to the specified location will need to tighten the nut inside stuck to the regulator is not random device rotation.

2, the powder outlet fitted with four magnetic devices, grinding pad wear iron adsorption machine running the process to ensure food hygiene and safety of dry;

3, the connecting shaft shorter, and disassembly is easy.

Operation and adjustment

1, the mill should be placed in a fixed, solid level desktop or table, solid wood is better. The iron of the motor below the four screw holes with a long screw through the screw holes for the motor iron firmly fixed on the desktop or table (cupboard); between the motor and desktop pad soft (rubber pad), vibration reduction, better mute.

2, the motor cover should be fixed on the desktop or cabinet should make separate motor cover and motor iron, do not close the iron, iron and motor cover to prevent start running after the vibration and resonance, and then the short screws to the motor cover lock tight.

3, the machine will cover open, then the disc fixed to the connection axis, and then two thumbs to press on in the disc if the disc can freely telescopic disc and connecting the shaft with the And then covered with the cover, tighten the locking nut, flak power, turn on the switch, check whether the mill operation according to the specified direction, sound, vibration is normal, if any abnormal sound or abnormal vibration should be shut down to check to troubleshoot problems up to normal in order to restart.

4, turn on the power, running about one minute, the material into the hopper, tighten the regulator to the appropriate location, open the tailgate of the cutting, the material slowly flows into the milling chamber. Baffle opening, so as not to feed too fast, stuck motor. Common materials in general grinding twice, the first pass to take the rough grinding, fine grinding of the second pass.

5, the thickness of the mill depends on the gap between the two grinding, grinding gap to rely on the regulator to control, to indicate the thickness of the cover, when the regulator to the fine direction of regulation, two grinding the gap is narrowing, milling thinning; the contrary, the mill is thicker.

6, the adjustment range and intensity of the regulator, how to control the grinding friction of the sound and the sound of the motor running, you can ear to determine the grinding by more closely, the sound is even more sound even more acute; grinding depends on failed to exercise stringent or separation, soft voice.

7, a separate grinding particularly high oil content materials such as sesame, walnut, peanut, because such materials, particularly high oil content can only be ground into meal, ground, a lot of oil to penetrate out, will make the powder turned into pulp shape. So grinding oil content of particular materials, the regulator not adjusted too tight, grinding gap to maintain a little closer to even complete separation can be ground into powder (granular). Of the above materials need to wear very thin, need to with no oil or low oil content of materials, high oil content and low (no) oil content materials ratio: 1:4 to 1:5, and taken to the mill twice. first pass rough grinding, fine grinding of the second pass.

8, grinding and static wear the handling of the film: in the disc fixed grinding, installed in the grinding chamber for static grinding. The fixed grinding three screws removed, the grinding can be removed. The grinding material for pig iron, pig iron hardness of about 52 °, hardness, elasticity is poor. Replace the mill films, the screws can not screw too tight, prevent grinding fracture.

Note

1, the mill must be external circuit protection (overload protection) devices to protect the motor and personal safety.

2, the machine can only grind dry materials, the material the more dry, can grind more finely.

3,380 V mill required of a professional electrician to install, ensure that the mill to operate in accordance with the provisions of the direction of, in order to ensure that the milling effect. As the power shortage of the motor burned belong to the operating side, the company is not responsible for the warranty.

4,220 V mill required of a professional electrician external standard ground, in order to avoid electrostatic motor hood and nose.

5 Mill to be fixed in the desktop and on the counter of a solid and stable level, in order to maximally reduce the vibration and noise.

6, under 18 people, more than 65-year-old, mentally handicapped and slow movement, without study and training, not carefully review the personnel manual, and will not be allowed to operate this machine.

7, in the process, as a result of power outages and other reasons, suddenly shut down, crushing cavity residual materials must be cleared before they can start again.

8, such as machine parts are badly worn or damaged should be promptly repaired or replaced.

9, the machine starts, should be operating normally before discharge processing, pay attention to the feed rate to prevent motor overload boring machine.

10, each with the end of the machine, the inside of the machine should be clean, dry and ventilated.

11, the machine a long time when not in use, should be cut off external power supply. Machine to not set to flat, above, do not put heavy objects.

12 year warranty, the man-made damage caused by improper use, normal wear and tear, not a warranty. Need to return to the sales unit or the manufacturer for repair, transportation costs borne by the purchaser.

Processing range:

Variety of food: sesame seeds, walnuts, rice, black rice, soybeans, mung beans, red beans, peanuts, lotus seeds, corn, sorghum, barley, buckwheat, oats, etc.;

(2) a variety of dry herbs: Chinese yam, almonds, Poria, dates, Gorgon fruit, wolfberry, barley, hawthorn fruit, Chinese yam, Radix, red beans, donkey-hide gelatin, frankincense, dodder seed, angelica, Codonopsis and so on.

(3) Other materials: ordinary chemical materials.

Motor special instructions:

As we all know, the machinery is driven by motor, the motor power and quality determines the quality and life of the machine. Xu Lang produced the 820-grain cereals mill in particular the use of Weihai, Shandong Pacific Cima Electric Co., Ltd. "Bao" brand motor, power for the GB 1.8KW definitely not shoddy, to underreporting. "Bao" brand motor, "China Famous Trademark", "Chinese famous brand", the "national exemption product" title "product strong standard certification, EU CE certification" a series of honorary titles, "Wen Po" motor manufacturers, regardless of strength, quality, service or reputation is second to none in the country, and other small motor factory is second to none. Cereals milling machine manufacturers, the "treasure" motor as the driving force of the mill, Xu Lang was the only one, from this perspective alone, Xu Lang Machinery domestic and foreign customers is definitely a more responsible the.

Wenbao motor more, please visit our "treasure text" Electric official website to view validation: http://www.wenbao.com/changmao2.htm |